How to DIY make EPS Packaging ?

DIY making EPS packaging can be very easy and simple,it just costs a small amount of money by a small tool.It involves a simple process that can be accomplished with minimal tools and materials.Come and let's DIY EPS Packaging.

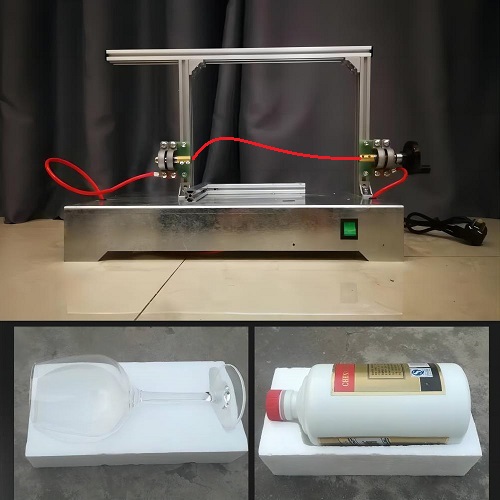

The small hot wire foam cutter for EPS packaging can help you.The operation is very simple. Here's a step-by-step guide for operation and cutting EPS packaging:

1. **Gather EPS Brick Materials:**

- EPS packaging: The material you want to cut

- Manual hot wire cutter: A device with a heated wire that melts EPS foam

- Ruler or straightedge: For making straight cuts size

- Marker: For marking the desired cutting lines

- Protective gloves and eyewear: For safety

2. **Heat the Hot Wire Cutter:**

- Plug the hot wire cutter into an electrical outlet and turn it on.

- Allow the hot wire to heat up completely.

4. **Cutting Process:**

- Manually drop the hot wire cutter down to EPS brick,rotate the hot wire handle for round packaging.Or,push the EPS brick after your drop the handle for square packaging.

- The hot wire will melt through the EPS foam, creating a clean and precise cut.

5. **Finishing Touches:**

- Once the cut is complete, lift the hot wire handle.

- Dispose of any EPS foam scraps responsibly.

Additional Tips:

- Practice cutting on scrap EPS foam before attempting to cut the actual packaging.

- Use a slow and steady hand to ensure precise cuts.

- Keep the hot wire cutter moving continuously to prevent burning the EPS foam.

- Always wear protective gloves and eyewear when working with hot wire cutters.

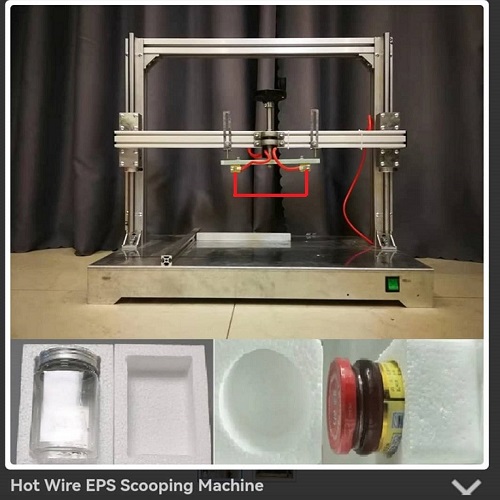

Either you want to make square or round shape EPS packaging in bulk qty,you will need the continuous hot wire foam cutter.

Here comes another method for continuous making EPS Packaging.You just put your EPS panels on the table of another hot wire foam cutter,it automatically feed and position itself,then hot wires scoop the panels.As the panel moves forward,the vertical hot wires and one horizontal hot wire will slice the scooped panels into individual packaging.You can set up all parameters in the control display screen to control speed,stroke timing etc.

Youtube Video @