Benefits of CNC EPS foam cutting machine

CNC Foam cutting machine is a very effective way to make custom shapes from foam. It's better than using an electric knife because it cuts more cleanly and the blade is always cold, meaning that you can cut foam without worrying about whether it will burn or create toxic fumes. There are several types of foam cutting machines, each with their own advantages. A hot wire cutter is a popular option. This type of machine uses small spools of wire that heat up on one end and then burn into the foam. It's as simple as feeding the wire through a hole in the foam and out the other end. The heated wire will melt its way through the foam, producing a clean edge free of residue or burnt marks.

CNC foam cutting machines are similar to CNC routers, which are used to cut wood, but they use a different method to achieve similar results. Instead of pushing a cutting bit through material in a straight line, this machine moves the bit back and forth at an angle until it has removed whatever shape has been programmed into the computerized control system. The amount of time this takes is measured in minutes rather than hours. Once you have your model, you can sand it down and coat it with spray paint or resin for added strength and protection against moisture.

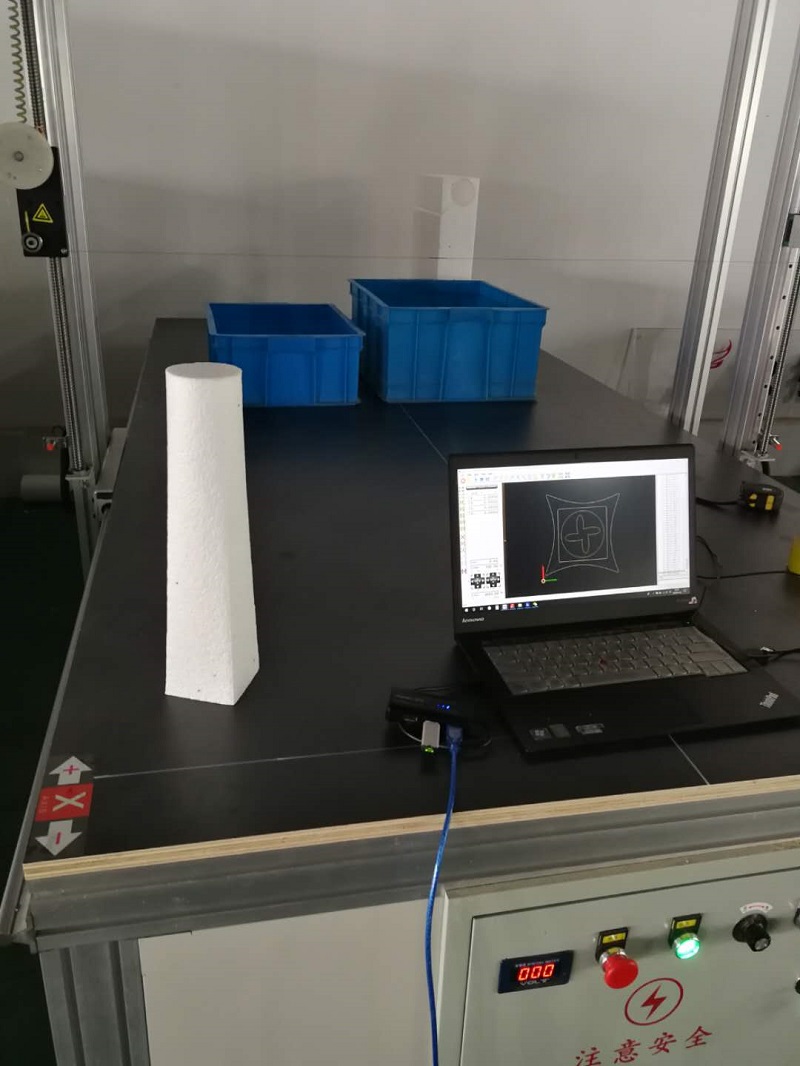

Our foam cutting machine analyzes your design and cuts the foam precisely to your specifications. The machine consists of a computer, a hot wire cutter, and a vacuum table for holding the workpiece. The operator programs the machine using a software package called GRBL, which is based on g-code. The software translates your design into g-code instructions for the hot wire cutter, allowing you to specify exactly where you want each cut made. It's simple: by telling the computer where you need cuts and how deep they should be, and then loading up the material on the vacuum table, you're ready to go!

The benefits of using this method for cutting foam are numerous. Since all of the cuts are made at once, there are no additional processing steps needed to finish your object after it's been cut. That's not only a time saver—it also means that you don't have to worry about possible distortions or warping due to thermal changes in your material during an extended cutting process. And because no glue is used when creating these objects—just two sheets of foam—they're lightweight and easy to transport around.

Myaid Machinery supply CNC foam cutting machine from large scale plant in China,the machine is international standard under our factory system for quality control.welcome to visit and see machines.