Detailed Presentation of Fast Wire Machine

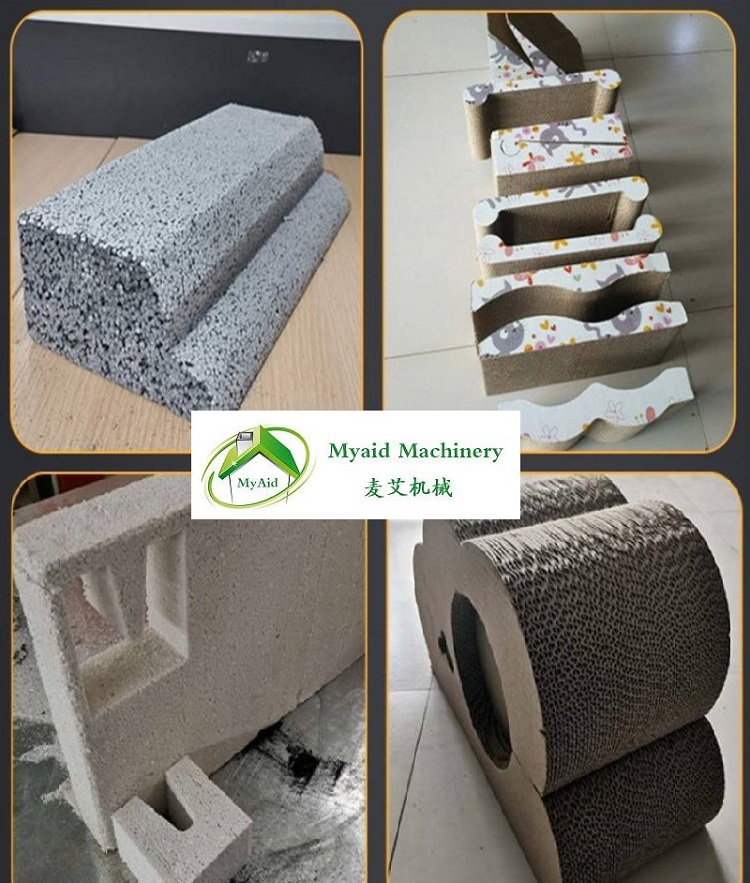

We are going to introduce our fast wire contour cutting machine,it is a CNC foam cutting machine.With the machine,you can cut many materials such as rigid PU and flexible PU,PVC,PE,EPS,EVA,rock wool and phenol foams.The machine can reach a cutting speed up to 5270mm/min,while as for the ordinary machines,it can reach 3000mm/min.The machine has a large cutting force that the driving motor has a power of 3kw while for the ordinary machines,it is only 2.2kw.Also,the CNC foam cutting machine has a cutting accuracy of +- 0.5mm which can quickly cut the circle with a radius of over R5mm.The fastest cutting speed can reach up to 10,000mm/min for special machine.

The mechanical parts of the fast wire machine has three main parts including control cabinet,gantry and working table.

Let’s see the control cabinet first,it is an industrialized computer fixed on the cabinet.The operating system is an XP.The AutoCAD can be used to draw the shapes of cutting materials that we want to cut.We can simply draw the path that we want to cut our materials in it.Also,you can see we have these buttons that they are used to switch on and off the machines,we have this red button to completely switch off all electricity for fast wire machine.

Now,the next part we are going to explain the electrical part of the fast wire machine.As you can see the wires inside of control cabinet.We have air switch which is four functions:First one is:when the short circuit protection circuit is short circuit,it will automatically disconnect from the circuit without manual control which can protect personal safety.The second function is:Once the isolation circuit is higher than the limit coefficient,there will be safety hazards.The air switch can isolate the unsafe current.The 3rd function is current limiting. When a higher current is generated,the air switch will disconnect the electrical connection between the electrical appliance and the electrical parts preventing the electrical appliance from being burned out.The 4th function is overload protection.The air switch plays an overload protection role when the circuit cannot bear the load.

This one is our wiring box of fast wire machine.It is used to protect and connect wires.Also here,we have control card for machine which is used for realizing the connection on control between the machine and computer,and also the communication and docking between computer and machine body.We have also our switching power supply which is used for reducing the input voltage to supply the applicable voltage for the components.So,we can say,its purpose is to stabilize the voltage in the control system.

The next here we have Y axis serve drive and also we have here X axis servo drive.Y axis servo drive is used to control the servo motor of machine’s lifting.And X axis servo drive is used to control the servo motor of machine table.So,the purpose of all these servo drives are to control movement of motors and to check fault or alarm of the servo motors.Also here,we have the frequency converter which can adjust the rotating speed of guiding wheels for cutting wire.

The next one here we have is the terminal blocks.As you can see these are called all terminal blocks and this terminal blocks are used for connecting the power lines in the circuit and also here we have our relay,this relay as yours is to control the switching on and off of the circuit and the next one here we have AC contactor.This one is used to connect and disconnect the lines or frequently control the operation of motors and other equipment.The final one here we have the thermal relay,it is used for overload protection of a synchronous Motors.Now let's talk about the cutting part of our machine,as you can see this is the cutting frame of the machine and also here we have a motor of three kilowatt ABB frequency conversion.It is imported from Taiwan, this motor is mainly for driving the cutter wheel which is the cutting point of this machine.so the first one is driving or cutter wheel.These are that transition Wheels.This one here we have here,this is a tension wheel and also this is the cutter wheel and the driving motor has driven to rotate this cutter wheel through the synchronous belt, so that this cutter will drive our abrasive wire which is cutting the material.

Now let's talk about our data sync system of the fast wire contour cutting machine.As you can see here the ground material on the working table during the cutting process by our Action System,this system has an air element and also an air outlet the ground material will be done through. I've done The Cutting force and speed stability are wrestling abroad because for the normal machines, the diameter or nothing will has only 300 millimeter and Servo driver it is only 2.2 kilowatt power.

Let me explain how the fast wire machine works?At the top of our photo frame as you can see we have absorbed drive.And under the super drive, we have the gearbox and this is our Palm screw. The Cutting frame can be moved up and down motivated by the circle motor to drive the high Precision basket through the five percent planetary reducer.There are two types of working table: one is fixed, one is movable.The gantry moves up and down,the table moves forward and backward to get 2D cutting designs.

The above is my introduction for our fast wire machine,welcome to visit us if you want to have more info. For the machine.Thank you.